Production Process

The manufacturing methods of seamless steel tube include hot rolling and cold drawing.

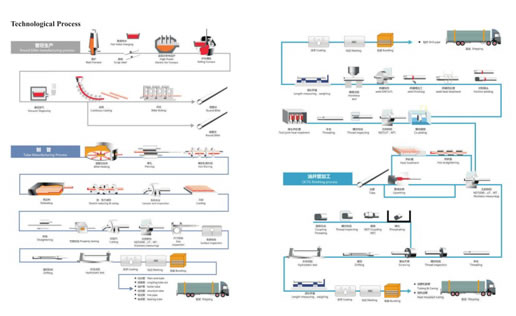

1. Hot-rolled or Extruded Seamless Steel Pipe Round Pipe Billet → Heating → Punching → Three-Roller Skew Rolling, Continuous Rolling or Extruding → Pipe Detaching → Micro Tension Sizing or Reducing → Cooling → Straightening → Hydrostatic Test or Inspection → Marking → Warehousing

- The material for rolled seamless steel tube is round pipe billet. This round billet can be cut into billet material with the length of one meter by cutting machines. Then it is conveyed to the smelting furnace for heating treatment with the temperature of 1200℃. We use hydrogen or acetylene as fuel. It is critical to control the temperature inside the furnace. After heat treatment, round billets will be punched by pressure punching machine.

- The most widely used punching machine for seamless steel pipe or seamless steel tube is cone-shaped roller puncher, featuring high production efficiency, good product quality and large hole enlargement. It can punch a variety of steels. After punching, round billet will go through successively skew rolling, continuous rolling and extruding by three-roller. After extruding, it should be detached for sizing. The sizing mill rotates in high speed into seamless steel pipes to punch holes through tapered bit. The inside diameter of seamless steel tube is determined by the length of outside diameter of drill bit of sizing mill. After sizing, steel tube enters the cooling tower for spray cooling. After cooling, pipes will be straightened.

- After straightening, seamless steel pipes are sent by conveyor belt to the metal inspection machine for internal inspection. If there are cracks and air bubbles inside the pipe, they will be found out. After quality testing, steel pipes should go through hand sorting. We use paint to spray number, specification and batch number. Then they are sent to the warehouse by crane.

2. Cold-drawn or Cold-rolled Seamless Steel Tube Round Pipe Billet → Heating → Punching → Pipe Head Treatment → Annealing → Acid Pickling → Coating Oil (Copper Plating) → Multi-pass Cold Drawing or Cold Rolling → Pipe Billet→ Heat Treatment → Straightening →Hydrostatic Test or Inspection → Marking → Warehousing

- Compared to hot rolling method, cold drawing method is more complex. The first three steps are similar with hot rolling production process. After punching, round billet will encounter pipe head or pipe end treatment and annealing. After annealing, we use special acidic liquid to do acid-pickling.

- After acid-pickling, we coat oil on the surface of seamless steel pipes. Then they go through multi-pass cold drawing or cold rolling, pipe billet and heat treatment. After heat treatment, they will be straightened. After straightening, seamless steel tubes are sent by conveyor belt to the metal inspection machine for internal inspection. If there are cracks and air bubbles inside the pipe, they will be found out. After quality testing, steel pipes should go through hand sorting.

- After quality testing, we use paint to spray number, specification and batch number. Then seamless steel pipes are sent to the warehouse by crane.

3. According to different manufacturing methods, there are hot-rolled pipe, cold-rolled pipe, cold drawn pipe and extruded pipe. Hot-rolled seamless steel tube is often produced on the automatic pipe mill. In order to get seamless steel pipes with smaller dimension and higher quality, we usually adopt cold drawing method or the combination of hot rolling and cold rolling.

- Home

- About Us

- - Group Overview

- - Company Profile

- - Brand Development Path

- - FAQ

- - R&D Strength

- - Project Achievements

- - Why choose us

- - Download

- News

- Products

- API 5L Line Pipe

- - Onshore Line pipe

- - Offshore Line pipe

- - Through Flowline(TFL)

- - PSL-2 Line Pipe Applied in Marine

- - Acid Corrosion Resistant PSL-2 Line Pipe

- - PSL-2 Sour Service Line Pipe

- - DNV ABS LR API Line Pipe

- - X52 X60 X70 X80 QS Line Pipe

- - Coating of Line Pipe

- API 5CT

- - API 5CT Series Coupling

- - API 5CT Series Tubing

- - API 5CT Series Casing

- - API 5CT Coupling Stock

- - API 5CT Pup Joint

- JST Special Series of Tubing and Casing

- - Perforating Gun Pipe

- - Collapse Resistant Casing

- - Ultra High-Strength Casing

- - 3Cr Corrosion Resistant Tubing & Casing

- - Anti-H2S Corrosion Tubing

- - CO2 Corrosion Resistant Tubing

- - Low Temperature Service Tubing and Casing

- - Heavy Oil Thermal Pipe

- - Premium Connection

- API 5DP Drill Pipe

- Anticorrosion Steel Pipe

- International Standard

- - ASTM/ASME Standard

- - EN Standard

- - DIN Standard

- - JIS Standard

- Steel Tube Applications

- Steel Tube Process

- Quality

- - Certificates

- - Production Process

- - Online Test

- - Physical and Chemical Test

- - Quality Assurance

- - Technical Services

- - After Service

- - Cost Savings

- Views

- - Cooperation and Communication

- - Steel-Making Mill

- - Tube-Making Mill

- - Tube Processing Mill

- - Heat Treatment Mill

- - Online Test

- - Physical and Chemical Test

- - Key Equipment

- - Products Details

- - Higher Steel Grade Product

- - Packaging and Transportation

- - Warehouse & Inventory

- Environment

- - Training

- - Work in JST

- Careers

- Contact Us

English

English Español

Español Русский

Русский العربية

العربية